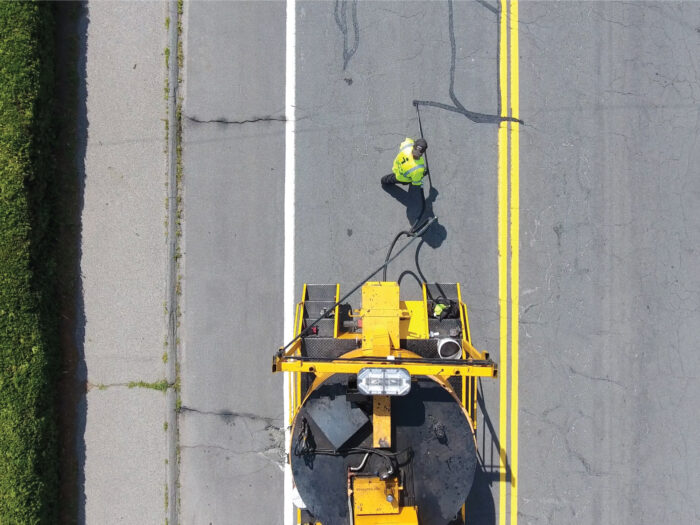

Saw & Seal.

Although it might seem counterintuitive on the surface, sawing and sealing is one of the most effective ways to protect our roads from harsh conditions, especially here in the Northeast with our wide-ranging temperature extremes. Installing dedicated control joints provides the extra flexibility some of our pavements need.

Process

A process involving laying new pavement, such as hot mix asphalt or micro surfacing, is performed on the surface of the road. Then, a new joint is sawed into the surface at a predetermined point, and this new joint is filled with an appropriate crack sealant material.

Benefits

- Installing control joints during rehabilitation or preservation projects is a proactive way to protect pavements

- Control joints make surfaces more flexible, giving them additional durability to survive harsh weather conditions

- Control joints prevent other cracks from forming randomly on the surface

Consider Saw & Seal when

you’re constructing a new road or rehabilitating an old one in an area where weather conditions can be harsh and rapidly changing.

Request a Specification or Professional Evaluation

Looking for a treatment recommendation on a particular road, need more details on one of our processes, have a network management question, or just looking for more information with a personal touch?