Hot-Applied Mastics.

Pavement defects come in all kinds of shapes and sizes, and hot-applied mastics are a versatile tool for repairing wider cracks, potholes and other areas too small for paving. The pourable and self-adhesive blend of high-performance asphalt binder and engineered aggregates can be used in a wide variety of applications to stop water infiltration and restore ride quality.

Process

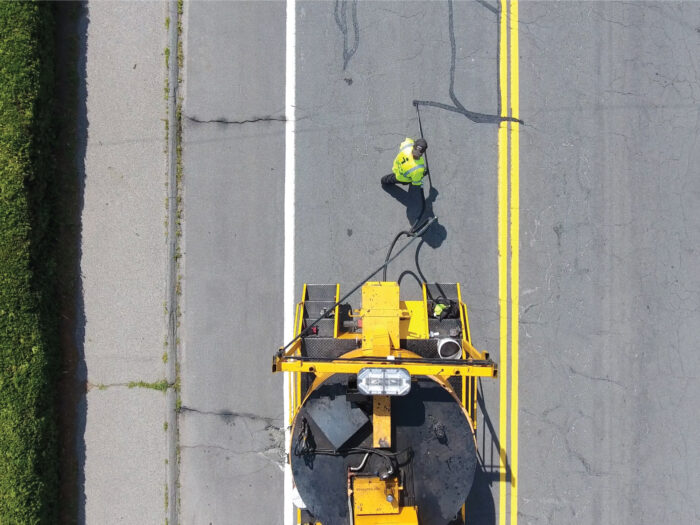

Blocks of the mastic material are melted and kept heated at about 400 degrees F in a hot-oil circulating kettle with constant agitation to keep the aggregate suspended uniformly throughout the binder. After carefully cleaning and drying the distressed areas to be repaired, the mastic is poured from the melting kettle into the pavement voids and finished with hand tools. Additional friction aggregate may be broadcast over the finished surface in areas requiring higher skid resistance.

Benefits

- Extremely flexible yet resistant to rutting across a wide range of temperatures

- No compaction required to achieve 100% density

- Provides a waterproof, air-tight seal

- Will adhere to asphalt and concrete surfaces

- Long-lasting, high-performance material and repair

Consider Hot-Applied Mastics when

when you have wide cracks, potholes or voids around utility castings to be repaired and are looking for a long-lasting solution.

Request a Specification or Professional Evaluation

Looking for a treatment recommendation on a particular road, need more details on one of our processes, have a network management question, or just looking for more information with a personal touch?