Paver-placed Stabilized Full Depth Reclamation.

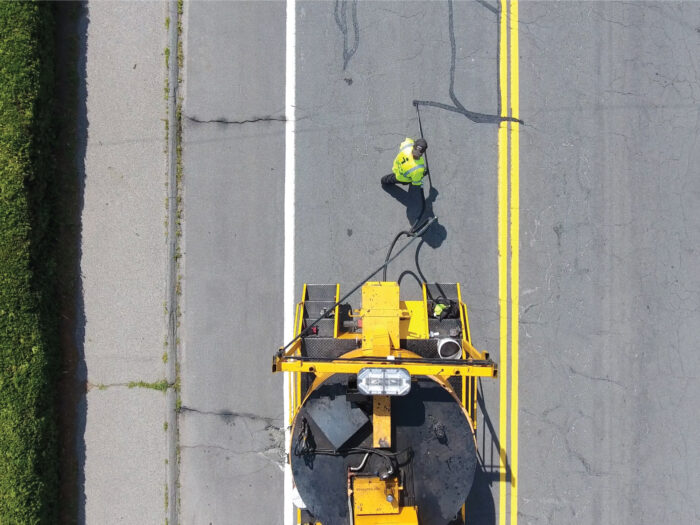

Sometimes a road deteriorates to a point that preservation treatments are no longer an option. Paver-placed Stabilized Full Depth Reclamation (SFDR) recycles pavement with performance additives that not only strengthen the recycled layer but also allows the road to remain open to traffic.

Process

Paver-placed Stabilized Full Depth Reclamation is a process that recycles existing asphalt and subbase in one continuous operation. Adding Portland cement and foamed-liquid asphalt stabilizers to the pulverized existing material creates a long-lasting base layer up to 8" thick.

Benefits

- Fully engineered process to recycle and reinstall in one continuous process

- Recycles pavement and subbase

- No windrows or motor graders necessary

- Reduces time and disruptions commonly found with traditional FDR

- Greatly reduces traffic disruption, project duration, and environmental impacts

- Stabilizers add a structural benefit to the recycled layer

- Reduce Greenhouse Gas Emissions by up to 60%

Consider Paver-placed Stabilized Full Depth Reclamation when

Your road has 4” or less of existing asphalt and CIR is not an option due to the road having an inadequate base.

“After doing Paver-Placed Stabilized Full Depth Reclamation for the first time, it far exceeded my expectations. Similar to Cold-In-Place recycling, there was very little disturbance to the residents. Additionally, the cost was about 10% less than a traditional FDR project and we performed structural testing that proved the recycled layer met the design strength.”

— Paul Pacheco, Highway Superintendent, Dartmouth, MA

Request a Specification or Professional Evaluation

Looking for a treatment recommendation on a particular road, need more details on one of our processes, have a network management question, or just looking for more information with a personal touch?