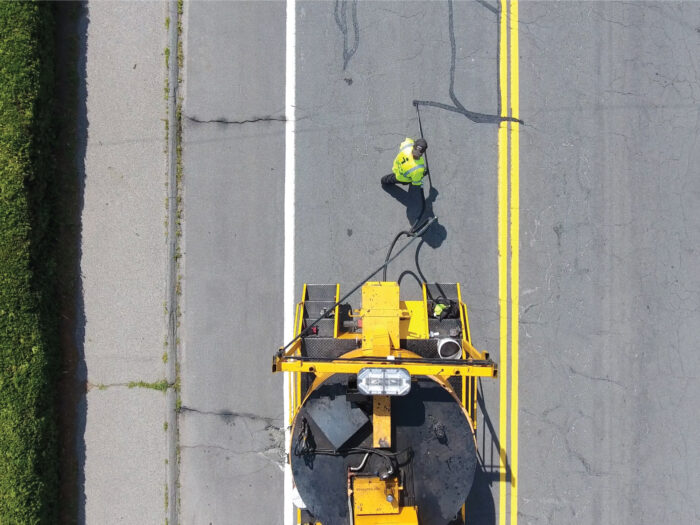

Cold In-place Recycling.

No matter how bad a road condition may be, the material itself can still be useful. Cold In-place Recycling (CIR) takes existing asphalt pavement and recycles it in a cost-effective, long-lasting road rehabilitation technique.

Process

In one continuous operation, the top 2 to 5 inches of distressed asphalt are cold-milled to produce reclaimed asphalt pavement (RAP). The RAP is then mixed with strengthening additives and placed back onto the existing roadway.

Benefits

- Up to half the cost of traditional total reconstruction methods

- Reuses 100% of existing material and lowers greenhouse gas emissions by up to 90%

- Faster construction times compared with conventional reclamation or reconstruction

- Longer lasting than shallow mill-and-fill, and extends road life by 15 to 20 years

Consider Cold In-place Recycling when

you’re looking for a cost-effective, environmentally friendly way to repair a poor road with reduced traffic and neighborhood disruption.

“The Town of Milford has been using the Cold-In-Place Recycling with foamed asphalt process provided by indus since 2018. We find it most beneficial on our heavy traffic, commercial roadways where construction disruptions must be kept to a minimum. The treatment has allowed us to recycle deeper than traditional mill & fill at a comparable cost while eliminating distresses up to 5” deep. By adding a 1.5” HMA wearing surface, it increases the structural capacity of the road and we have not found any reflective cracking after 5 years unlike a mill & fill. When we have a road that has good structure but a surface that is beyond preservation, we’ve found CIR to provide the best value.”

— Scott Crisafulli, Highway Surveyor, Milford, MA

“"Central Turnpike is a heavily travelled commercial roadway with a lot of truck traffck and an AADT over 6,000 vehicle trips per day. I needed a cost-effective solution that still provided me the strength to handle the heavy loading. I chose Cold-In-Place Recycling to a depth of 5" with a 2" HMA wearing surface at a cost of $16.37/sy. This ended up 66% less than using our traditional method of full depth reclamation which would have cost us $27.15/sy!”

— Matthew Stencel, Highway Superintendent, Sutton, MA

Request a Specification or Professional Evaluation

Looking for a treatment recommendation on a particular road, need more details on one of our processes, have a network management question, or just looking for more information with a personal touch?